The Real Cost of 'We'll Document It Later': Why Manufacturing Documentation Never Happens (And What It's Actually Costing You)

Most manufacturers know their documentation is outdated, but it never makes it to the top of the list. Here's what that delay is actually costing you and why it keeps happening.

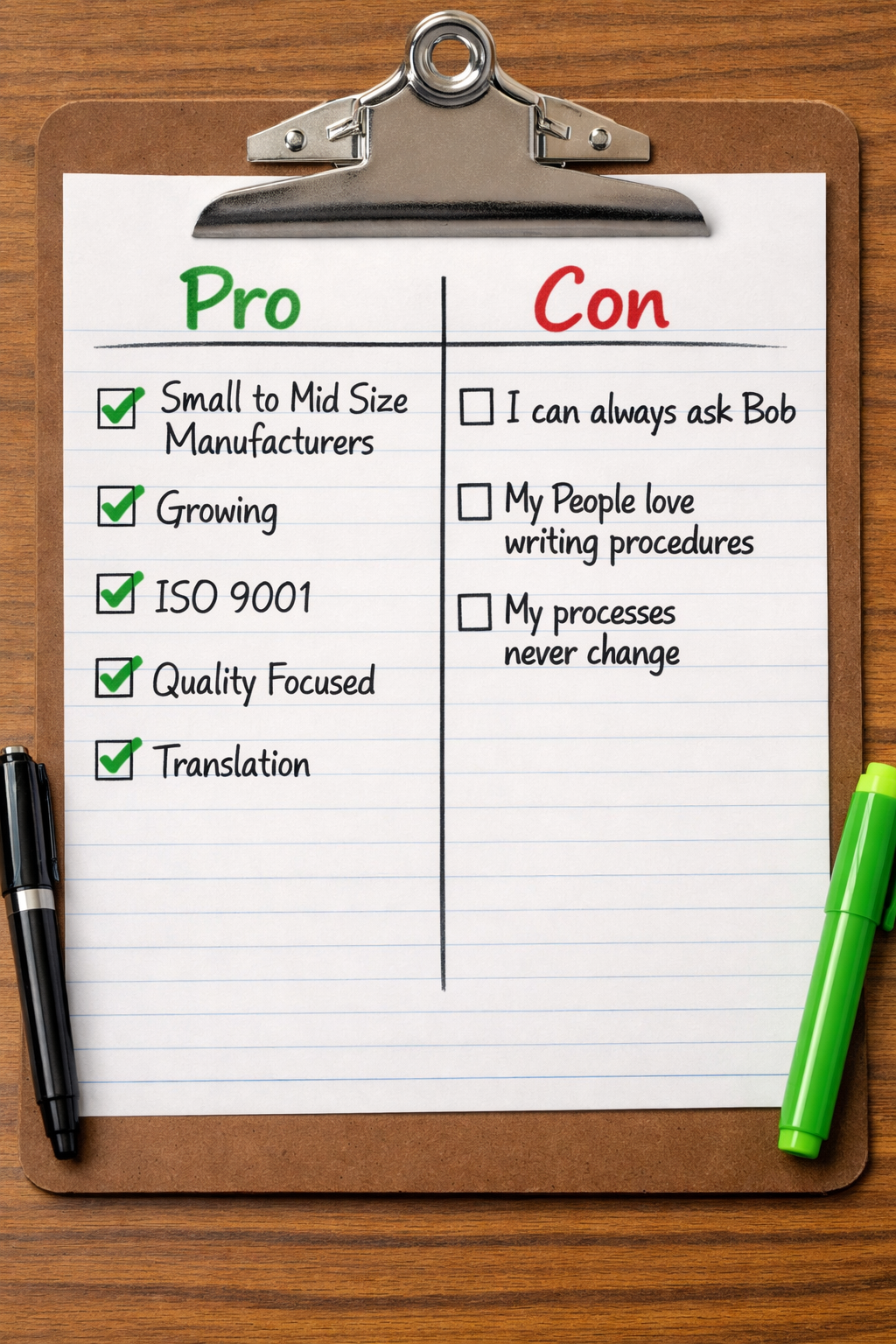

Who MODocs is For (And Who It’s Not)

MODocs isn’t just another document tool. It’s built for manufacturers serious about ISO 9001, training, and operational excellence. Here’s who it’s for and who it’s not.

How Mid-Sized Manufacturers Can Reach ISO 9001 Readiness in Days, Not Months

Manufacturers no longer need months of documentation work or costly consultants to get ISO 9001 ready. With MODocs’ integrated system, including: internal audits, training, translations, digital checklists, analytics, and Voice-to-SOP AI, companies can become audit-ready weeks.

How to Capture Tribal Knowledge Before It Walks Out the Door

When experienced employees leave, so does critical know-how. Learn how leading manufacturers are using AI and digital SOP tools like MODocs to capture tribal knowledge before it disappears, keeping production consistent, training faster, and quality high.

Your Documentation Is Wrong (And It's Not Your Fault)

Most manufacturing documentation doesn’t match what really happens on the floor and it’s not your fault. MODocs lets operators capture reality in minutes, turning tribal knowledge into accurate SOPs without slowing production.

The New Era of Onboarding: How MODocs Transforms Documentation into Interactive Training

Traditional onboarding slows teams down. MODocs turns your documentation into guided, interactive training, helping new hires learn faster, stay consistent, and preserve your team’s expertise.

Why Documenting Processes Still Takes Hours (and How to Fix It in Minutes)

Process documentation is notoriously slow, often taking hours for something simple. But it doesn’t have to be. Learn how manufacturers are cutting documentation time from 1.5 hours to 15 minutes with conversational SOPs and checklists.

From Tribal Knowledge to Structured Processes: How One Manufacturer is Scaling Smarter with MODocs

As manufacturers scale, the need to capture tribal knowledge and formalize processes becomes urgent. In this case study, we share how one growing manufacturer used MODocs to transform scattered notes into structured documentation, streamline onboarding, and improve efficiency, setting the stage for scalable growth.

Scaling Beyond 50 Employees: How Manufacturers Can Conquer Documentation, Onboarding, and Process Control

Hitting 50 employees is a major milestone for any manufacturer, but it’s also the tipping point where informal processes, verbal instructions, and ad-hoc onboarding can no longer keep pace with operational complexity. Learn how to capture and share knowledge, streamline training, and standardize processes so your team can grow without sacrificing quality or culture.

The Hidden Cost of Inconsistency: Why Standards Matter More Than Ever in Manufacturing

When manufacturers lack clear standards for time, materials, and quality, it creates ripple effects across the entire organization. From missed deadlines and wasted materials to stressed-out teams and lost profits. Not knowing your true baseline costs your business more than you think.

Overcoming Audit Anxiety: How MODocs Helps Manufacturers Prepare for ISO Certification

ISO certification is a major milestone, but getting there is not easy. Manufacturers face a maze of documentation, training, and audit hurdles. MODocs helps teams streamline audits, stay compliant, and preserve tribal knowledge, all while reducing downtime and defects.

Harnessing AI: Revolutionizing Fault Libraries in Medical Device Manufacturing

Medical device manufacturers face relentless pressure to improve quality and reduce costly defects. Traditional fault libraries help, but they’re not enough. By combining AI with frontline knowledge and real-time SOP tracking, manufacturers can create smarter, continuously evolving fault libraries that prevent repeat issues before they happen. Here's how AI-powered documentation is reshaping efficiency, compliance, and quality across the line.

Why Quality is the Secret Weapon for Growing Manufacturers

When you are growing fast, it is tempting to treat quality as something you'll fix later. But successful manufacturers know better. In this post, we unpack how quality-focused processes help you scale without breaking and how MODocs turns SOP chaos into operational clarity.

Demystifying AI for Manufacturers

AI isn't magic, it's a tool. In this post, we explore how manufacturers can separate hype from reality and apply AI where it delivers real-world value. From automation audits to governance frameworks, learn how MODocs helps teams avoid costly mistakes and turn AI into operational excellence.

How to Stand Up Manufacturing Processes Faster: Anywhere You Move

Rapidly standing up processes in new locations, without the headaches

Moving or expanding manufacturing operations? MODocs helps teams replicate, adapt, and activate their processes in new facilities with speed and confidence. Here’s how we make transitions seamless when speed and precision matter most.

You Have Documentation… Now What? Turning Procedures into Real-Time Process Insight

Documentation is just the beginning. Learn how growing manufacturers can transform SOPs into real-time insights that drive quality, accountability, and measurable improvement, without the data collection headache.

The Creation and Importance of SOPs (Standard Operating Procedures) in Growing Manufacturing Companies

Scaling a manufacturing business without strong SOPs is like building on sand. Learn why growing manufacturers need clear, up-to-date processes and how MODocs makes creating, managing, and improving SOPs faster and easier than ever.

The Power of Checklists: Transforming Manufacturing with Precision and Efficiency

Small mistakes lead to big problems, but checklists are the key to precision, quality, and efficiency in manufacturing. From eliminating errors to streamlining compliance, digital checklists are transforming the industry. Discover how MODocs makes it effortless to turn your SOPs into smart, automated workflows, boosting productivity without the paperwork. Ready to see the future of manufacturing? Let’s build it together.

The Future of Document Control: Empower Your Team with Dynamic Versioning

Discover how MODocs is redefining process documentation for modern manufacturing teams. From capturing best practices on the fly to embedding training directly into daily workflows, our latest innovations in dynamic document control keep your team aligned, informed, and always ready for what’s next. Say goodbye to outdated SOPs and hello to living documents that evolve with your operation—without ever slowing you down.

How AI is Transforming Manufacturing Documentation (And How You Can Benefit)

Manufacturing documentation is broken, but it doesn’t have to be. Processes evolve, but outdated SOPs and lost tribal knowledge slow teams down. MODocs transforms documentation into a seamless, real-time process using AI-powered voice and text capture. No more bottlenecks, no more missing updates, just clear, professional SOPs created effortlessly.

Ready to document smarter? See how MODocs can revolutionize your workflow.